Fiberglass Insulation for Pole Barn: Is It the Right Solution?

Pole barns can be drafty and hard to regulate. If you constantly battle temperature swings, understanding your insulation options can save you frustration—and money.

Fiberglass insulation works well in most pole barns because it efficiently slows heat loss, is affordable, and is widely available. It fits between framing members, helping keep interiors comfortable year-round.

Pole barns have unique challenges. If you want lower energy bills and less condensation, choosing the right insulation makes a big difference. I have looked at many options and tested solutions in real-world settings. I want to explain what I found so you can decide for yourself.

Can you use fiberglass insulation in a pole barn?

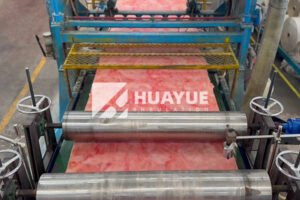

Fiberglass insulation is popular for use in pole barns since it is easy to install, resists moisture when properly protected, and helps prevent drafts.

The installation of fiberglass batts or rolls between the pole barn’s framing is straightforward. With a vapor barrier, it reduces moisture problems. Its R-value offers reliable thermal efficiency, helping to lower heating and cooling costs.

When working with pole barns, I always check for air leaks around the posts and beams. Gaps are common at the eaves and corners. Before installing fiberglass, I make sure the surface is clean and dry. Lining up batts snugly is important. I use a vapor barrier to cover the insulation—not just to keep moisture out, but also as a safeguard against unwanted drafts and pests. For best results, I often recommend closed-cell foam around tricky spots, then fiberglass batts for the main areas. This keeps the barn warmer and drier. The table below shows how fiberglass compares with other common insulation choices:

| Insulation Type | Moisture Resistance | Installation Difficulty | R-Value per Inch | Initial Cost |

|---|---|---|---|---|

| Fiberglass Batts | Moderate | Easy | 3.2–3.8 | Low |

| Spray Foam | High | Difficult | 6+ | High |

| Blown Cellulose | Moderate | Moderate | 3.2–3.8 | Medium |

| Rigid Foam Board | High | Moderate | 4–6 | High |

Fiberglass is user-friendly and cost-effective. Most barns I have worked on use it for the bulk of wall and ceiling insulation. However, every barn is unique. I always recommend checking for moisture before you start your project.

What is the best insulation to use in a pole barn?

Spray foam insulation offers the highest efficiency for pole barns, but fiberglass batts remain the most practical choice due to affordability and easy installation.

When I talk to barn owners, I ask about budget, climate, and usage. Spray foam works great for airtightness and moisture control. But for most people, cost and simplicity matter more. Fiberglass is easy for DIY installation and works well in most climates. High-density foam boards add insulation in very cold areas. I sometimes combine foam boards on the outside walls with fiberglass inside, maximizing comfort. Here’s a breakdown of insulation types and suitability for pole barns:

| Type | Pros | Cons | Best Used For |

|---|---|---|---|

| Spray Foam | Best airtightness, moisture | Expensive, needs expertise | Unheated barns, wet areas |

| Fiberglass Batts | Cheap, easy to install | Needs vapor barrier | General use, DIY |

| Foam Board | Good for walls, floors | Pricey, rigid | Extra wall protection |

| Cellulose | Good acoustic insulation | Can hold moisture | Quiet areas, dry barns |

Fiberglass batts often win for ease and price. Nearly all my barn customers use it for primary insulation, sealing gaps first for better results. For high-value equipment or livestock, I may suggest spray foam in problem areas, but fiberglass suits a wide range of needs for pole barns.

Does fiberglass insulation count as fire blocking?

Fiberglass insulation is naturally fire resistant but does not qualify as fire blocking under building codes.

Fiberglass does not burn and can slow fire spread. However, fire blocking means material that stops flames and smoke from passing through hidden spaces in buildings. Building codes require special barriers—often lumber or drywall—for fire blocking. Fiberglass alone does not satisfy these requirements. Whenever I insulate a barn, I make sure there is solid blocking at floors, attics, and penetrations as required by local code. I use fiberglass for thermal insulation and install fire-resistant barriers for code compliance.

If your barn’s design has concealed spaces or large wall or ceiling cavities, you must use approved fire block materials. Here’s a simple table that describes what counts as fire blocking:

| Material | Fire Blocking | Fire Resistant | Notes |

|---|---|---|---|

| Fiberglass | No | Yes | Slows spread, not blocking |

| Drywall | Yes | Yes | Standard for walls |

| Solid Lumber | Yes | Yes | Used for framing fire stops |

| Spray Foam | No* | Yes | Needs special coating |

(*Spray foam may count with approved intumescent coatings.)

I always discuss fire safety with customers. Fiberglass is a good choice to slow flames, but local codes must be followed for full fire blocking.

What’s the most efficient way to heat a pole barn?

Radiant heating or forced air systems are the most efficient heating methods for a well-insulated pole barn.

When I look at pole barns, insulation is step one. Heating makes sense only once you minimize heat loss. I see radiant floors used in workshops and garages. They keep the whole space evenly warm. For smaller barns, a forced air heater does fine, especially if you use ceiling fans to mix the warmth. Electric infrared heaters are another easy choice for spot heating. But I always say: Insulate first. Poor insulation means money wasted no matter your heat source. Find and seal all gaps, then pick your system. Here is a simple overview:

| Heating Type | Efficiency | Upfront Cost | Best for |

|---|---|---|---|

| Radiant Floor | High | High | Workshops, garages |

| Forced Air Furnace | Medium-High | Medium | Large spaces |

| Infrared Heater | Medium | Low | Small areas, spot heat |

| Wood Stove | Medium | Medium | Basic barns, dry areas |

I always match heating to how the barn is used. For livestock, equipment, or workspace, radiant systems work best for comfort. For occasional use, forced air or infrared heaters are cost-effective if you insulate first.

Conclusion

Choosing fiberglass insulation for a pole barn is a practical, cost-effective solution when installed with proper vapor barriers and fire protection measures.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions